A concrete driveway is a durable and long-lasting investment that can provide reliable and attractive service for your parking and access needs for many years, if not decades. However, like any other surface or structure, a concrete driveway requires regular maintenance and care to keep it in top shape and prevent any premature damage or deterioration.

In this article, we’ll discuss the typical maintenance schedule and tasks that a concrete driveway needs over its lifetime, from routine cleaning and inspection to occasional repairs and upgrades. We’ll also provide some tips and best practices for each maintenance step, as well as some common problems and solutions that you may encounter along the way.

Regular Maintenance Schedule

The first and most important aspect of maintaining a concrete driveway is to establish and follow a regular schedule of cleaning, inspection, and preventive care. The frequency and intensity of these tasks can vary depending on the age, condition, location, and usage of your driveway, but in general, here are some guidelines for a typical maintenance timeline:

Weekly Cleaning

On a weekly basis, it’s a good idea to clean your concrete driveway of any loose dirt, debris, or stains that may accumulate on the surface. This can be done with a simple broom, leaf blower, or garden hose, depending on the type and amount of soiling. Regular sweeping or rinsing can help prevent the buildup of abrasive particles, organic matter, or chemicals that can etch or discolor the concrete over time.

In addition to dry sweeping or wet rinsing, you may also need to do some spot cleaning of any oil, grease, or other stubborn stains that may occur from vehicles, equipment, or spills. For these types of stains, you can use a mild detergent or degreaser solution and a stiff brush or pressure washer to loosen and remove the residue. Be sure to rinse the area thoroughly afterwards to avoid leaving any slippery or corrosive substances on the surface.

Monthly Inspection

On a monthly basis, it’s a good idea to perform a more thorough inspection of your concrete driveway to look for any signs of wear, damage, or deterioration that may require attention or repair. This can be done visually by walking around the entire surface and noting any cracks, chips, spalls, or other defects that may have developed since the last inspection.

Some common things to look for during a monthly inspection include:

- Cracks: Any cracks that are wider than 1/8 inch, longer than 1 foot, or have uneven edges or displacement may indicate underlying structural issues or settlement that may require professional evaluation and repair.

- Scaling: Any flaking, peeling, or popping of the surface layer of concrete, especially in areas exposed to freeze-thaw cycles or deicing salts, may indicate improper finishing, curing, or protection that may require resurfacing or sealing.

- Stains: Any discoloration or darkening of the concrete, especially in areas exposed to moisture, shade, or organic matter, may indicate mold, mildew, or algae growth that may require cleaning or biocide treatment.

- Drainage: Any standing water, puddles, or erosion around the edges or joints of the driveway may indicate poor grading, slope, or drainage that may require regrading, repaving, or installation of additional drainage features.

If you notice any significant or concerning issues during your monthly inspection, it’s best to document them with photos or notes and consult with a professional concrete contractor or engineer to determine the best course of action for repair or maintenance.

Seasonal Care

In addition to weekly cleaning and monthly inspection, it’s also important to provide some seasonal care and protection for your concrete driveway, especially in areas with extreme or variable weather conditions. The specific tasks and timing of seasonal maintenance can vary depending on your local climate and environment, but here are some general guidelines:

- Spring: In the spring, it’s a good time to do a thorough cleaning and resealing of your concrete driveway to remove any winter debris, salt, or damage and restore the protective barrier of the surface. This can involve pressure washing, stain removal, crack repair, and application of a high-quality sealer or coating that is compatible with your concrete mix and exposure conditions.

- Summer: In the summer, it’s important to protect your concrete driveway from excessive heat, sunlight, and moisture that can cause thermal stress, fading, or staining. This can involve providing shade or cooling with trees, awnings, or reflective coatings, as well as avoiding parking hot vehicles or equipment on the surface for extended periods.

- Fall: In the fall, it’s a good time to prepare your concrete driveway for the winter by removing any leaves, debris, or stains that may trap moisture or chemicals on the surface, as well as checking and repairing any cracks, joints, or drainage issues that may worsen with freezing and thawing cycles.

- Winter: In the winter, it’s critical to avoid using any deicing salts, chemicals, or abrasives on your concrete driveway that can cause scaling, spalling, or corrosion of the surface. Instead, use sand, kitty litter, or other traction aids that are less harmful to concrete, and remove any snow or ice accumulation promptly to prevent moisture infiltration and damage.

By following a regular and seasonal maintenance schedule, you can help extend the life, performance, and appearance of your concrete driveway, and avoid costly and disruptive repairs or replacements down the road.

Annual Assessment

Finally, it’s recommended to conduct an annual assessment of your concrete driveway to evaluate its overall condition, identify any major issues or needs, and plan for any future maintenance, repairs, or upgrades. This can involve a more detailed and comprehensive inspection than the monthly checks, as well as some testing, measurement, and documentation of the surface and subgrade properties.

Some key aspects to assess during an annual evaluation include:

- Surface profile: Use a straightedge, level, or profiler to measure the flatness, smoothness, and consistency of the surface, and compare it to the original specifications or standards for the driveway. Any significant deviations or irregularities may indicate settlement, heaving, or other structural issues that may require leveling, grinding, or resurfacing.

- Surface texture: Use a visual or tactile assessment to evaluate the roughness, traction, and drainage of the surface, and compare it to the desired or required slip resistance and water management for the driveway. Any excessive smoothness, slickness, or ponding may indicate worn or polished aggregates, sealers, or slopes that may require texturing, grooving, or regrading.

- Surface hardness: Use a rebound hammer, penetration probe, or other nondestructive testing device to measure the hardness, strength, and durability of the surface, and compare it to the expected or design values for the concrete mix and age. Any significant softness, weakness, or deterioration may indicate poor curing, overloading, or chemical attack that may require strengthening, topping, or replacement.

- Surface chemistry: Use a pH meter, chloride test, or other chemical analysis kit to measure the acidity, alkalinity, and salt content of the surface, and compare it to the safe or acceptable limits for the concrete mix and exposure conditions. Any excessive acidity, carbonation, or chloride penetration may indicate corrosion, leaching, or reactions that may require neutralization, desalination, or cathodic protection.

Based on the results and findings of the annual assessment, you can develop a prioritized and budgeted plan for any maintenance, repair, or upgrade activities that may be needed to restore, enhance, or extend the serviceability and value of your concrete driveway. You can also use the assessment data to track and compare the performance and deterioration of your driveway over time, and make informed decisions about its future use, care, and replacement.

Cleaning Procedures

One of the most essential and frequent maintenance tasks for a concrete driveway is regular cleaning to remove any dirt, debris, stains, or contaminants that may accumulate on the surface over time. The specific cleaning methods and products can vary depending on the type, severity, and location of the soiling, but here are some general procedures and best practices for cleaning concrete driveways:

Debris Removal

The first step in cleaning a concrete driveway is to remove any loose debris, such as leaves, twigs, rocks, or litter, that may be present on the surface. This can be done with a broom, leaf blower, or vacuum, depending on the size and type of debris. Be sure to dispose of the debris properly in a trash can or compost bin, and avoid sweeping or blowing it into the street, storm drain, or neighboring properties.

For heavier or stuck-on debris, such as mud, gum, or tar, you may need to use a putty knife, scraper, or wire brush to loosen and remove the material. Be careful not to scratch or gouge the concrete surface, and use a gentle touch and appropriate tools for the job.

Stain Treatment

The next step in cleaning a concrete driveway is to identify and treat any stains or discolorations that may be present on the surface. The most common types of stains on concrete driveways include:

- Oil and grease stains from vehicles, equipment, or cooking

- Rust stains from metal furniture, tools, or irrigation systems

- Leaf and organic stains from trees, plants, or animals

- Mold and mildew stains from moisture, shade, or poor drainage

- Paint and chemical stains from spills, overspray, or reactions

Each type of stain may require a different cleaning approach and product, depending on its composition, age, and penetration. Here are some general guidelines for treating common concrete stains:

- Oil and grease stains: Use a degreaser, enzyme cleaner, or poultice to break down and absorb the oil, and then rinse with hot water and detergent. For fresh stains, sprinkle with baking soda, cornstarch, or cat litter to absorb the excess oil before cleaning.

- Rust stains: Use a rust remover, oxalic acid, or poultice to dissolve and lift the rust, and then neutralize with baking soda or ammonia. For stubborn stains, use a wire brush or sandpaper to remove the surface rust before cleaning.

- Leaf and organic stains: Use a detergent, bleach, or oxygenated cleaner to break down and remove the organic matter, and then rinse thoroughly with water. For deep or old stains, use a pressure washer or scrub brush to agitate and lift the stain before cleaning.

- Mold and mildew stains: Use a mold and mildew remover, bleach, or vinegar to kill and remove the growth, and then rinse thoroughly with water. For prevention, improve the drainage, ventilation, and sunlight exposure of the affected area, and apply a mold-resistant sealer or coating.

- Paint and chemical stains: Use a paint stripper, solvent, or poultice to dissolve and remove the paint or chemical, and then rinse thoroughly with water. For stubborn or old stains, use a scraper, grinder, or sandblaster to remove the surface layer of concrete before cleaning.

When treating any stain on a concrete driveway, it’s important to test the cleaning product or method on a small, inconspicuous area first to ensure its safety and effectiveness, and to follow the manufacturer’s instructions and precautions for use. It’s also important to protect yourself and the environment from any harmful or toxic chemicals, and to dispose of the cleaning waste properly in accordance with local regulations.

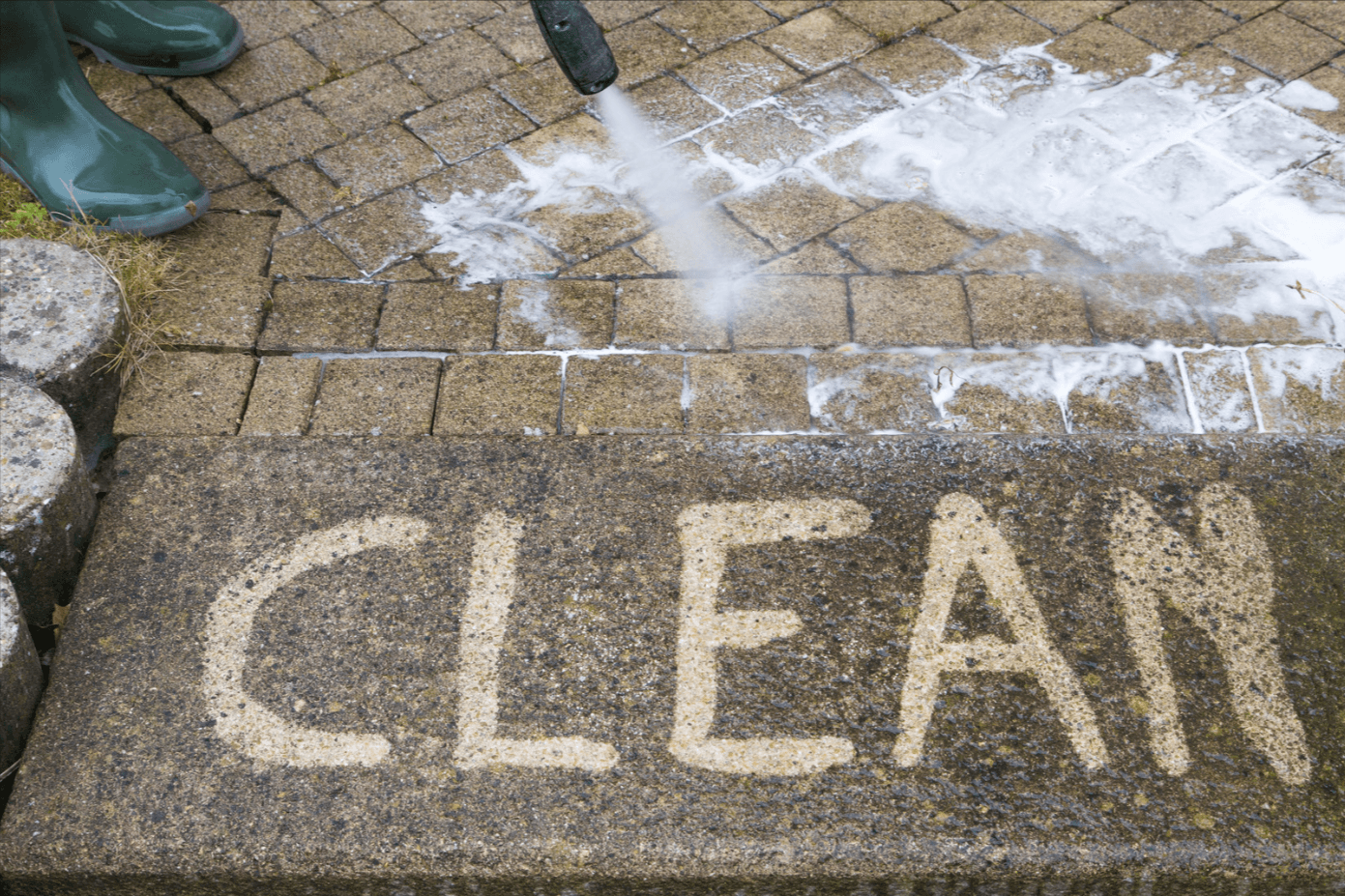

Pressure Washing

After removing the debris and treating the stains, the final step in cleaning a concrete driveway is to wash the entire surface with water and detergent to remove any remaining dirt, grime, or residue. The most effective and efficient way to do this is with a pressure washer, which uses high-pressure jets of water to blast away the soiling and rinse the surface clean.

When pressure washing a concrete driveway, it’s important to use the right equipment, settings, and techniques to avoid damaging or etching the surface, and to achieve a thorough and even cleaning. Here are some tips and best practices for pressure washing concrete driveways:

- Use a gas-powered or electric pressure washer with a minimum pressure of 2,000 psi and a maximum pressure of 3,500 psi, depending on the condition and strength of the concrete. Higher pressures may be needed for heavily soiled or stained areas, but can also cause more wear and tear on the surface.

- Use a wide-angle or rotary nozzle with a 25-degree or greater spray pattern to cover a larger area and reduce the impact force on the surface. Avoid using a zero-degree or pinpoint nozzle, which can concentrate the water pressure and cause streaks, lines, or damage on the concrete.

- Use a detergent or cleaning solution that is compatible with the pressure washer and the concrete mix, and apply it to the surface with a low-pressure spray or foam cannon before washing. Let the detergent dwell on the surface for a few minutes to loosen and emulsify the soiling, but do not let it dry or harden on the surface.

- Hold the pressure washer nozzle at a consistent distance and angle from the surface, typically 12 to 18 inches away and 45 degrees from the perpendicular, and move it in a steady, overlapping pattern to ensure even coverage and cleaning. Avoid holding the nozzle too close or too long on any one spot, which can cause etching, scarring, or erosion of the surface.

- Rinse the surface thoroughly with clean water to remove any remaining detergent, dirt, or debris, and to prevent any streaks, spots, or residue from drying on the surface. Use a lower pressure and wider nozzle for the final rinse to avoid any splash-back or over-spray onto adjacent surfaces or landscaping.

After pressure washing, allow the concrete driveway to dry completely before walking, driving, or parking on it, and inspect the surface for any signs of damage, wear, or unevenness that may require repair or resurfacing. If the driveway is due for resealing or coating, wait at least 24 to 48 hours after cleaning to ensure that the surface is fully dry and ready for the application.

Chemical Cleaning

In some cases, regular cleaning with water and detergent may not be enough to remove stubborn stains, buildup, or contaminants from a concrete driveway, and more aggressive or specialized cleaning methods may be needed. One of these methods is chemical cleaning, which uses acids, solvents, or other reactive substances to dissolve, etch, or lift the soiling from the surface.

Chemical cleaning can be effective for removing tough stains, such as oil, grease, rust, or paint, as well as for preparing the surface for resealing, staining, or overlaying. However, chemical cleaning can also be more hazardous and damaging to the concrete and the environment than other cleaning methods, and should be used with caution and proper protection.

Here are some common types of chemical cleaners used for concrete driveways, along with their benefits, drawbacks, and precautions:

- Acid cleaners: Acid cleaners, such as hydrochloric, phosphoric, or citric acid, are used to etch and dissolve mineral deposits, rust, or cement paste from the surface of the concrete. They can also be used to neutralize and remove efflorescence, which is a white, powdery substance that can form on the surface due to moisture and salt migration. However, acid cleaners can also erode and weaken the concrete, especially if used too frequently or at too high of a concentration, and can cause burns, fumes, or environmental damage if not handled and disposed of properly. When using acid cleaners, always wear protective gear, such as gloves, goggles, and a respirator, and follow the manufacturer’s instructions for dilution, application, and neutralization.

- Alkaline cleaners: Alkaline cleaners, such as sodium hydroxide, potassium hydroxide, or trisodium phosphate, are used to saponify and emulsify oil, grease, or organic stains from the surface of the concrete. They can also be used to brighten and whiten the surface, and to prepare it for resealing or coating. However, alkaline cleaners can also be corrosive and irritating to the skin and eyes, and can leave a residue on the surface that may interfere with the adhesion or appearance of sealers or coatings. When using alkaline cleaners, always wear protective gear and follow the manufacturer’s instructions for dilution, application, and rinsing.

- Solvent cleaners: Solvent cleaners, such as mineral spirits, xylene, or acetone, are used to dissolve and remove paint, tar, or polymer stains from the surface of the concrete. They can also be used to clean and degrease the surface before resealing or coating. However, solvent cleaners can also be flammable, toxic, and environmentally harmful, and can damage or discolor some types of concrete sealers or coatings. When using solvent cleaners, always work in a well-ventilated area, avoid smoking or sparks, and follow the manufacturer’s instructions for application and disposal.

- Enzymatic cleaners: Enzymatic cleaners, such as bacterial or fungal formulas, are used to biodegrade and remove organic stains, such as oil, grease, or food residue, from the surface of the concrete. They can also be used to control odors and prevent future staining by digesting the organic matter that attracts dirt and debris. However, enzymatic cleaners can also take longer to work than other types of cleaners, and may require multiple applications or extended dwell times to fully remove the stain. When using enzymatic cleaners, always follow the manufacturer’s instructions for application, dwell time, and rinsing, and avoid using them in extreme temperatures or pH conditions that may deactivate or denature the enzymes.

- When using any type of chemical cleaner on a concrete driveway, it’s important to test the product on a small, inconspicuous area first to ensure its safety and effectiveness, and to follow all the manufacturer’s instructions and precautions for use, storage, and disposal. It’s also important to protect any nearby vegetation, vehicles, or surfaces from overspray or runoff, and to neutralize or collect any cleaning waste before it enters the soil, groundwater, or storm drains.

- After chemical cleaning, it’s important to rinse the surface thoroughly with clean water to remove any remaining chemicals, residue, or contaminants, and to restore the normal pH and appearance of the concrete. Depending on the type and strength of the cleaner used, you may need to use a pressure washer, scrub brush, or neutralizing agent to ensure a complete and effective rinse.

- Damage Prevention

- In addition to regular cleaning and maintenance, another important aspect of preserving and extending the life of a concrete driveway is to prevent or minimize any damage or deterioration from external factors, such as weather, traffic, or chemical exposure. By taking some proactive and preventive measures, you can help avoid or delay the need for costly and disruptive repairs or replacements, and maintain the safety, functionality, and appearance of your driveway for longer.

- Here are some common types of damage that can affect concrete driveways, along with some tips and strategies for preventing or mitigating them:

- Weather Damage

- Concrete driveways can be susceptible to various types of weather-related damage, such as:

- Freeze-thaw damage: In cold climates, the repetitive freezing and thawing of water in the pores and cracks of the concrete can cause expansion, cracking, and spalling of the surface layer. To prevent freeze-thaw damage, it’s important to use air-entrained concrete with proper drainage and slope, and to avoid using deicing salts or chemicals that can aggravate the problem.

- Heat damage: In hot climates, the exposure to direct sunlight and high temperatures can cause the concrete to expand, warp, or discolor, especially if it has a dark or absorptive finish. To prevent heat damage, it’s important to use light-colored or reflective concrete with proper expansion joints and reinforcement, and to provide shade or cooling with trees, awnings, or coatings.

- Moisture damage: In humid or rainy climates, the exposure to excessive or prolonged moisture can cause the concrete to absorb water, develop efflorescence, or support mold and mildew growth, especially if it has poor drainage or ventilation. To prevent moisture damage, it’s important to use water-resistant or breathable concrete with proper grading and slope, and to seal or waterproof the surface regularly.

- Chemical Damage

- Concrete driveways can also be susceptible to various types of chemical-related damage, such as:

- Salt damage: The use of deicing salts, such as sodium chloride or calcium chloride, can cause scaling, spalling, and corrosion of the concrete surface, especially if it has a porous or weak finish. To prevent salt damage, it’s important to use alternative deicers, such as sand, kitty litter, or beet juice, or to apply a salt-resistant sealer or coating to the surface.

- Oil damage: The dripping or leaking of oil, gasoline, or other petroleum products from vehicles or equipment can cause staining, softening, and deterioration of the concrete surface, especially if it has a porous or unsealed finish. To prevent oil damage, it’s important to clean up any spills or leaks promptly, and to use an oil-resistant sealer or coating on the surface.

- Acid damage: The exposure to acidic substances, such as battery acid, cleaning agents, or fertilizers, can cause etching, pitting, and discoloration of the concrete surface, especially if it has a low pH or weak finish. To prevent acid damage, it’s important to avoid using or storing acidic materials near the driveway, and to neutralize any spills or splashes promptly with baking soda or lime.

- Impact Damage

- Concrete driveways can also be susceptible to various types of impact-related damage, such as:

- Cracking: The heavy or repeated loading of vehicles, equipment, or structures on the driveway can cause cracking, especially if the concrete has insufficient thickness, reinforcement, or support. To prevent cracking, it’s important to use proper base preparation, joint placement, and load distribution, and to avoid exceeding the design capacity of the driveway.

- Spalling: The impact or abrasion of heavy, sharp, or hard objects, such as rocks, tools, or snow plows, on the driveway can cause chipping, flaking, or breaking of the concrete surface, especially if it has a weak or brittle finish. To prevent spalling, it’s important to use a durable and impact-resistant finish, such as a hard-troweled or diamond-ground surface, and to remove any loose or protruding objects from the driveway.

- Settling: The shifting, sinking, or unevenness of the soil or subbase under the driveway can cause settling, cracking, or tripping hazards, especially if the concrete has inadequate compaction, drainage, or reinforcement. To prevent settling, it’s important to use proper subgrade preparation, compaction, and stabilization, and to install any necessary drainage or reinforcement features, such as perforated pipes, geotextiles, or wire mesh.

- To prevent or minimize these and other types of damage to your concrete driveway, it’s important to follow some general best practices, such as:

- Using high-quality and durable concrete mixes and finishes that are appropriate for your climate, traffic, and exposure conditions

- Installing and maintaining proper drainage, grading, and slope to avoid water ponding, erosion, or settling

- Sealing and protecting the surface regularly with compatible and effective sealers, coatings, or overlays

- Repairing any cracks, spalls, or other defects promptly and properly with suitable and durable patching or resurfacing materials

- Avoiding any excessive, abusive, or inappropriate use or loading of the driveway, and following any posted or recommended weight or speed limits

- Protecting the driveway from any external or environmental hazards, such as tree roots, animal burrows, or construction activities, and providing any necessary barriers, guards, or signage

- By taking these and other proactive and preventive measures, you can help ensure that your concrete driveway remains safe, functional, and attractive for many years to come, and avoid any premature or unnecessary maintenance or replacement costs.

- Repair Procedures

- Even with the best maintenance and prevention practices, concrete driveways can still develop various types of damage or deterioration over time, due to factors such as age, usage, or exposure. When this happens, it’s important to repair the damage promptly and properly to avoid any further or more serious problems, and to restore the safety, functionality, and appearance of the driveway.

- The specific repair procedures and materials can vary depending on the type, extent, and location of the damage, as well as the desired outcome and budget of the project. Here are some common types of concrete driveway repairs, along with some general guidelines and considerations for each:

- Crack Filling

- Cracks are one of the most common and visible types of damage on concrete driveways, and can range from small, hairline cracks to large, wide, or deep cracks that may indicate underlying structural or settlement issues. Depending on the size, depth, and cause of the cracks, they can be repaired with various types of crack fillers, such as:

- Epoxy fillers: Epoxy fillers are two-part, resin-based materials that are injected or poured into the cracks to bond and seal them, and can provide a strong, durable, and waterproof repair. Epoxy fillers are best suited for narrow, deep, or structural cracks, and can be colored or textured to match the existing concrete.

- Polyurethane fillers: Polyurethane fillers are single-part, foam-based materials that are injected into the cracks to expand and fill them, and can provide a flexible, resilient, and water-resistant repair. Polyurethane fillers are best suited for wide, shallow, or moving cracks, and can be sanded or painted to blend with the surrounding concrete.

- Cementitious fillers: Cementitious fillers are powder-based materials that are mixed with water or liquid latex to form a paste, and are troweled or brushed into the cracks to patch and level them. Cementitious fillers are best suited for small, surface, or cosmetic cracks, and can be colored or stamped to match the existing concrete texture.

- When filling cracks in a concrete driveway, it’s important to follow these general steps:

- Clean and prepare the cracks by removing any dirt, debris, or loose material with a wire brush, compressed air, or vacuum.

- Widen or rout the cracks with a crack chaser or grinder to create a uniform and controllable profile for the filler.

- Apply the filler according to the manufacturer’s instructions, using the appropriate tools and techniques for the specific product and crack size.

- Allow the filler to cure and harden according to the recommended time and conditions, and avoid any traffic or loading on the repaired area until fully cured.

- Seal or coat the repaired area and the surrounding concrete to protect and blend the repair, and to prevent any future cracking or damage.

- Surface Patching

- Surface patching is another common type of repair for concrete driveways that have minor or localized damage, such as spalls, pits, or scaling, due to factors such as impact, abrasion, or chemical exposure. Surface patching involves removing the damaged or deteriorated concrete to a sound and stable substrate, and then filling and leveling the area with a compatible and durable patching material, such as:

- Concrete patching compound: Concrete patching compound is a pre-mixed, cementitious material that is applied with a trowel or float to fill and level small to medium-sized surface defects, and can be textured or colored to match the existing concrete. Concrete patching compound is best suited for shallow, non-structural, or cosmetic repairs, and can be used on both horizontal and vertical surfaces.

- Polymer-modified mortar: Polymer-modified mortar is a custom-mixed, cement-based material that is enhanced with polymers, such as acrylic or latex, to improve its bonding, flexural, and waterproofing properties, and is applied with a trowel or brush to fill and level medium to large-sized surface defects. Polymer-modified mortar is best suited for deeper, structural, or load-bearing repairs, and can be used on both horizontal and vertical surfaces.

- Epoxy mortar: Epoxy mortar is a two-part, resin-based material that is mixed and applied with a trowel or spatula to fill and level small to medium-sized surface defects, and can provide a strong, durable, and chemical-resistant repair. Epoxy mortar is best suited for thin, non-structural, or decorative repairs, and can be used on both horizontal and vertical surfaces.

- When patching the surface of a concrete driveway, it’s important to follow these general steps:

- Remove the damaged or deteriorated concrete with a chisel, hammer, or saw to create a clean, sound, and rough surface for the patch to bond to.

- Apply a bonding agent or primer to the prepared surface to improve the adhesion and compatibility of the patch material.

- Mix and apply the patching material according to the manufacturer’s instructions, using the appropriate tools and techniques for the specific product and patch size.

- Finish and texture the patched area to match the surrounding concrete, using a trowel, broom, or stamp as needed.

- Cure and protect the patched area according to the recommended time and conditions, and avoid any traffic or loading on the repair until fully cured.

- Seal or coat the repaired area and the surrounding concrete to protect and blend the repair, and to prevent any future damage or deterioration.

- Joint Repair

- Joint repair is another important type of maintenance for concrete driveways that have joint-related issues, such as spalling, separation, or settlement, due to factors such as thermal expansion, load transfer, or subbase failure. Joint repair involves removing any damaged or deteriorated concrete along the joint edges, and then filling and sealing the joint with a compatible and flexible joint filler, such as:

- Backer rod: Backer rod is a foam or rubber cord that is inserted into the joint to provide a backing and depth control for the joint filler, and to prevent any adhesion or sagging of the filler. Backer rod is best suited for wide, deep, or irregular joint profiles, and can be used with various types of joint fillers.

- Silicone sealant: Silicone sealant is a one-part, elastomeric material that is gunned or poured into the joint to fill and seal it, and can provide a flexible, durable, and weatherproof joint repair. Silicone sealant is best suited for narrow, shallow, or regular joint profiles, and can be used on both horizontal and vertical surfaces.

- Polyurethane sealant: Polyurethane sealant is a one-part or two-part, elastomeric material that is gunned or poured into the joint to fill and seal it, and can provide a flexible, durable, and traffic-resistant joint repair. Polyurethane sealant is best suited for wide, deep, or irregular joint profiles, and can be used on both horizontal and vertical surfaces.

- When repairing the joints of a concrete driveway, it’s important to follow these general steps:

- Clean and prepare the joint by removing any dirt, debris, or old sealant with a wire brush, saw, or grinder, and ensure that the joint edges are sound and dry.

- Install any necessary backer rod or bond breaker tape to the proper depth and width, according to the size and shape of the joint and the type of sealant used.

- Apply the sealant according to the manufacturer’s instructions, using the appropriate tools and techniques for the specific product and joint profile, and ensure that the sealant is filled to the proper depth and width, and is tooled or smoothed to the desired shape and finish.

- Allow the sealant to cure and harden according to the recommended time and conditions, and avoid any traffic or loading on the repaired joint until fully cured.

- Inspect and maintain the repaired joint regularly, and reseal or replace the joint filler as needed to ensure its continued performance and durability.

- Resurfacing

- Resurfacing is a more extensive and comprehensive type of repair for concrete driveways that have widespread or severe damage, such as cracking, scaling, or unevenness, due to factors such as age, wear, or structural issues. Resurfacing involves applying a new layer of concrete or overlay material over the existing surface to restore its strength, smoothness, and appearance, and can be done with various types of resurfacing products, such as:

- Concrete overlay: Concrete overlay is a cementitious material that is mixed with water, polymers, and aggregates, and is poured or pumped over the prepared surface to a thickness of 1/4 to 1 inch, depending on the condition and profile of the existing concrete. Concrete overlay can be colored, textured, or stamped to achieve various decorative effects, and can provide a strong, durable, and load-bearing repair.

- Polymer overlay: Polymer overlay is a resin-based material that is mixed with fillers, pigments, and aggregates, and is applied over the prepared surface to a thickness of 1/16 to 1/4 inch, depending on the type and formulation of the polymer. Polymer overlay can be clear, colored, or patterned to achieve various decorative effects, and can provide a thin, seamless, and chemical-resistant repair.

- Micro-topping: Micro-topping is a thin, cementitious material that is mixed with polymers, fibers, and pigments, and is troweled or sprayed over the prepared surface to a thickness of 1/32 to 1/8 inch, depending on the number and direction of the coats. Micro-topping can be smooth, textured, or stenciled to achieve various decorative effects, and can provide a thin, uniform, and abrasion-resistant repair.

- When resurfacing a concrete driveway, it’s important to follow these general steps:

- Assess and prepare the existing surface by repairing any cracks, spalls, or other defects, and cleaning and profiling the surface to ensure proper adhesion and bonding of the resurfacing material.

- Prime the prepared surface with a bonding agent or primer, according to the manufacturer’s instructions, to improve the compatibility and performance of the resurfacing material.

- Mix and apply the resurfacing material according to the manufacturer’s instructions, using the appropriate tools and techniques for the specific product and application method, and ensure that the material is spread evenly and smoothly to the desired thickness and finish.

- Texture, color, or pattern the resurfaced area, if desired, using various tools, mats, or stencils, and follow the manufacturer’s instructions for the timing, sequence, and curing of the decorative treatments.

- Cure and protect the resurfaced area according to the recommended time and conditions, and avoid any traffic or loading on the repair until fully cured and hardened.

- Seal or coat the resurfaced area, if needed, to enhance its durability, stain resistance, and appearance, and follow the manufacturer’s instructions for the application and maintenance of the sealer or coating.

By following these repair procedures and best practices, you can help restore and extend the life, safety, and functionality of your concrete driveway, and avoid any further or more costly damage or deterioration. However, it’s important to remember that not all concrete driveway damage can or should be repaired by the homeowner, and that some types of repairs may require the expertise, equipment, and materials of a professional concrete contractor.

If you are unsure about the type, extent, or cause of the damage on your driveway, or if you are not confident or equipped to perform the repairs yourself, it’s always best to consult with a qualified and experienced contractor who can assess the situation, recommend the appropriate repair options, and ensure the quality and durability of the work.

Long-Term Protection

In addition to regular maintenance and timely repairs, another important aspect of preserving and enhancing the life and value of a concrete driveway is to provide long-term protection against various types of damage, deterioration, and exposure. By investing in some proactive and preventive measures, you can help extend the service life, performance, and appearance of your driveway, and avoid any premature or unnecessary replacement or rehabilitation costs.

Here are some common types of long-term protection for concrete driveways, along with some benefits, considerations, and applications for each:

Weather Protection

Weather protection involves using various methods and materials to shield or insulate the concrete driveway from the damaging effects of sun, rain, snow, and temperature changes. Some examples of weather protection for concrete driveways include:

- Sealers: Sealers are clear or colored liquids that are applied to the surface of the concrete to form a protective barrier against water, stains, and UV rays. Sealers can be penetrating or film-forming, and can enhance the color, gloss, and texture of the concrete. Sealers should be reapplied every 1-3 years, depending on the type and exposure of the driveway.

- Coatings: Coatings are thicker and more durable than sealers, and are applied to the surface of the concrete to provide a decorative and protective layer against weather, traffic, and chemicals. Coatings can be epoxy, polyurethane, or acrylic-based, and can be solid-color, multi-color, or clear. Coatings should be reapplied every 3-5 years, depending on the type and exposure of the driveway.

- Overlays: Overlays are cementitious or polymer-based materials that are applied over the existing concrete surface to provide a new, smooth, and weather-resistant finish. Overlays can be stamped, stenciled, or textured to mimic the look of brick, stone, tile, or wood, and can be colored or stained to match any design or style. Overlays should be reapplied every 10-20 years, depending on the type and exposure of the driveway.

Chemical Resistance

Chemical resistance involves using various methods and materials to protect the concrete driveway from the damaging effects of salts, oils, acids, and other chemicals that can stain, etch, or corrode the surface. Some examples of chemical resistance for concrete driveways include:

- Densifiers: Densifiers are liquid chemicals that are applied to the surface of the concrete to react with the free lime and calcium hydroxide in the cement paste, and form a harder, denser, and more chemical-resistant surface layer. Densifiers can be silicate, siliconate, or lithium-based, and can improve the abrasion, dusting, and stain resistance of the concrete. Densifiers should be reapplied every 2-5 years, depending on the type and exposure of the driveway.

- Stain-resistant sealers: Stain-resistant sealers are specialized sealers that are formulated with silicone, silane, or siloxane compounds to repel water, oil, and other liquids from penetrating and staining the concrete surface. Stain-resistant sealers can be clear or colored, and can maintain the natural look and breathability of the concrete. Stain-resistant sealers should be reapplied every 1-3 years, depending on the type and exposure of the driveway.

- Chemical-resistant coatings: Chemical-resistant coatings are specialized coatings that are formulated with high-performance resins, such as novolac epoxy, vinyl ester, or polyurea, to withstand exposure to strong acids, alkalis, solvents, and other chemicals. Chemical-resistant coatings can be solid-color, multi-color, or clear, and can provide a seamless and impermeable barrier against chemical attack. Chemical-resistant coatings should be reapplied every 5-10 years, depending on the type and exposure of the driveway.

Load Management

Load management involves using various methods and materials to reinforce or distribute the loads and stresses on the concrete driveway, and prevent any cracking, settling, or failure due to heavy vehicles, equipment, or usage. Some examples of load management for concrete driveways include:

- Reinforcement: Reinforcement involves adding steel bars, mesh, or fibers to the concrete mix or surface to increase its tensile strength, flexural strength, and crack resistance. Reinforcement can be installed during the initial construction or repair of the driveway, and can be sized and spaced according to the expected loads and stresses. Reinforcement should be protected from corrosion and bonded to the concrete for optimal performance.

- Thickened edges: Thickened edges involve increasing the thickness of the concrete slab at the perimeter or joints of the driveway to provide additional support and load transfer. Thickened edges can be formed with wood or plastic forms, and can be tapered or stepped to match the profile of the driveway. Thickened edges should be at least 8 inches thick and extend at least 12 inches beyond the edge of the driveway.

- Subgrade improvement: Subgrade improvement involves stabilizing or strengthening the soil or aggregate base under the concrete driveway to provide a firm and uniform foundation for the slab. Subgrade improvement can be done with compaction, geotextiles, chemical additives, or drainage systems, and can reduce the risk of settlement, pumping, or erosion. Subgrade improvement should be designed and installed according to the soil type, water table, and climate conditions of the site.

Drainage Maintenance

Drainage maintenance involves using various methods and materials to manage and remove the water and moisture from the surface and subgrade of the concrete driveway, and prevent any damage or deterioration due to freezing, thawing, or erosion. Some examples of drainage maintenance for concrete driveways include:

- Sloping and grading: Sloping and grading involve shaping and angling the surface of the concrete driveway to direct the water and runoff away from the edges, joints, and foundation, and towards a suitable outlet or drainage system. Sloping and grading should be done with a minimum slope of 1/4 inch per foot, and should be smooth and uniform to avoid any ponding or puddling.

- Joint sealing: Joint sealing involves filling and sealing the gaps and cracks between the concrete slabs or segments with a flexible and waterproof material, such as silicone, polyurethane, or asphalt-based sealants, to prevent any water or debris from entering and eroding the subgrade. Joint sealing should be done with a backer rod and tooled to a concave shape for optimal adhesion and movement.

- Drainage systems: Drainage systems involve installing various devices and features to collect, convey, and discharge the water and runoff from the surface and subgrade of the concrete driveway, such as catch basins, trench drains, French drains, or permeable pavers. Drainage systems should be designed and sized according to the rainfall intensity, soil permeability, and site topography, and should be maintained and cleaned regularly to avoid any clogging or failure.

By implementing these and other long-term protection measures for your concrete driveway, you can help ensure its durability, functionality, and aesthetics for many years to come, and avoid any costly and disruptive repairs or replacements due to weather, chemical, load, or drainage-related damage or deterioration. However, it’s important to remember that no protection measure is perfect or permanent, and that regular inspection, maintenance, and reapplication are still necessary to ensure the continued effectiveness and performance of the protection systems.

Frequently Asked Questions

To help you better understand the maintenance and repair needs of your concrete driveway, here are some answers to common questions and concerns:

What is the most important maintenance task for a concrete driveway?

The most important maintenance task for a concrete driveway is regular cleaning and sealing to remove any dirt, stains, or contaminants that can damage or degrade the surface, and to protect it from water, chemicals, and UV exposure. By keeping the driveway clean and sealed, you can help prevent or delay many types of damage and deterioration, such as cracking, scaling, spalling, or discoloration, and extend its service life and appearance.

What are the best products for cleaning and sealing a concrete driveway?

The best products for cleaning and sealing a concrete driveway depend on the type, age, condition, and exposure of the driveway, as well as your desired outcome and budget. In general, it’s best to use pH-neutral, biodegradable, and non-abrasive cleaners that are specifically formulated for concrete, and avoid using any acidic, alkaline, or solvent-based cleaners that can etch, stain, or damage the surface.

For sealing, it’s best to use a high-quality, breathable, and UV-resistant sealer that is compatible with your concrete mix and exposure conditions, and avoid using any cheap, generic, or incompatible sealers that can peel, yellow, or trap moisture in the concrete. Some good options for concrete driveway sealers include acrylic, silicone, or polyurethane-based sealers that are clear, colored, or textured, and provide a durable and attractive finish.

How often should I hire a professional for maintenance and repair of my concrete driveway?

The frequency of hiring a professional for maintenance and repair of your concrete driveway depends on the age, condition, and usage of the driveway, as well as your own skills, time, and equipment. In general, it’s recommended to hire a professional for any major or complex repairs, such as resurfacing, joint replacement, or subgrade stabilization, and for any specialized or decorative treatments, such as staining, stamping, or coating.

For routine maintenance, such as cleaning, sealing, or crack filling, you may be able to do it yourself with the right products and tools, or hire a professional every 1-3 years for a more thorough and effective job. However, if you notice any signs of significant damage, deterioration, or failure, such as wide cracks, deep spalls, or uneven settlement, it’s best to hire a professional as soon as possible to assess the situation and recommend the appropriate repair options.

How much does it typically cost to repair or maintain a concrete driveway?

The cost of repairing or maintaining a concrete driveway can vary widely depending on the type, extent, and location of the damage or maintenance needed, as well as the contractor, materials, and methods used. As a rough estimate, here are some typical cost ranges for common concrete driveway repairs and maintenance:

- Cleaning: $0.20 to $0.50 per square foot for DIY cleaning, or $50 to $200 for professional cleaning

- Sealing: $0.50 to $2.00 per square foot for DIY sealing, or $200 to $1,000 for professional sealing

- Crack filling: $1 to $3 per linear foot for DIY crack filling, or $100 to $500 for professional crack filling

- Patching: $2 to $5 per square foot for DIY patching, or $200 to $1,000 for professional patching

- Joint repair: $5 to $10 per linear foot for DIY joint repair, or $500 to $2,000 for professional joint repair

- Resurfacing: $3 to $7 per square foot for DIY resurfacing, or $1,000 to $5,000 for professional resurfacing

- Replacement: $5 to $15 per square foot for professional replacement, or $3,000 to $10,000 or more for a typical driveway

Keep in mind that these are just rough estimates, and that the actual cost of your concrete driveway repair or maintenance may be higher or lower depending on your specific situation and requirements. To get a more accurate and detailed estimate, it’s always best to consult with a qualified and experienced concrete contractor who can assess your driveway and provide you with a written scope of work and price quote.

What should I do if I notice any damage or issues with my concrete driveway between maintenance visits?

If you notice any damage or issues with your concrete driveway between maintenance visits, the first step is to assess the severity, extent, and cause of the problem, and determine whether it poses any safety or structural risks to your driveway or property. If the damage is minor, superficial, or cosmetic, such as small cracks, chips, or stains, you may be able to repair or clean it yourself with the appropriate products and tools, or wait until the next scheduled maintenance visit to address it.

However, if the damage is major, deep, or widespread, such as wide cracks, large spalls, or uneven settlement, or if it is caused by a serious or ongoing problem, such as tree roots, drainage issues, or heavy loads, it’s best to contact a professional concrete contractor as soon as possible to assess the situation and recommend the appropriate repair or maintenance options. In some cases, delaying or ignoring the damage can lead to further or more costly repairs or failures down the road, so it’s important to act promptly and proactively to address any issues with your concrete driveway.

Conclusion

In conclusion, a concrete driveway is a significant and valuable investment for any homeowner, and one that requires regular maintenance and care to ensure its long-term durability, functionality, and appearance. From routine cleaning and sealing to timely repairs and protection, there are many tasks and considerations involved in maintaining a concrete driveway over its lifetime, and each one plays a critical role in preserving and enhancing its performance and value.

By understanding the common types of damage and deterioration that can affect a concrete driveway, as well as the best practices and products for preventing, repairing, and protecting it, you can help extend its service life, improve its safety and aesthetics, and avoid any premature or unnecessary replacement or rehabilitation costs. Whether you choose to do the maintenance and repairs yourself or hire a professional contractor, it’s important to stay proactive, informed, and committed to the upkeep and improvement of your concrete driveway, and to address any issues or concerns as soon as they arise.

At Pro Concreters Mackay, we understand the importance and complexity of maintaining and repairing concrete driveways, and we have the expertise, experience, and equipment to provide the highest quality and value for our customers. From routine cleaning and sealing to custom resurfacing and protection, we offer a wide range of services and solutions to meet the specific needs and goals of each project, and to deliver exceptional results and satisfaction.

Our team of skilled and certified professionals follows the latest industry standards and best practices for concrete maintenance and repair, and uses only the best materials, tools, and techniques to ensure the durability, performance, and appearance of our work. We also provide clear and detailed communication, documentation, and warranties for our services, and strive to exceed our customers’ expectations and earn their trust and referrals.

Whether you need a one-time repair or a long-term maintenance plan for your concrete driveway, we invite you to contact us today for a free consultation and estimate. We will be happy to assess your driveway, answer your questions, and provide you with the information and options you need to make an informed and confident decision about your concrete maintenance and repair needs.

For more information about our concrete driveway maintenance and repair services, as well as our other residential and commercial concreting solutions, please visit our website or call us today. We look forward to serving you and helping you enjoy a safe, beautiful, and long-lasting concrete driveway for your home or business.

Concrete Footings and Foundations

Concrete Pathway and Footpath Installation

Concrete Pool Surrounds Installation